RED SEAL MEASUREMENT

At Liquid Handling Equipment, Inc. in Charlotte, NC, we also offer reliable flow meters and metering devices from Red Seal Measurement meters, the company behind the Neptune Flowmeters specializing in refined fuels and industrial liquids applications. Red Seal Measurement portfolio of products are know for their peak performance, reliability, and unparalled service since 1892.

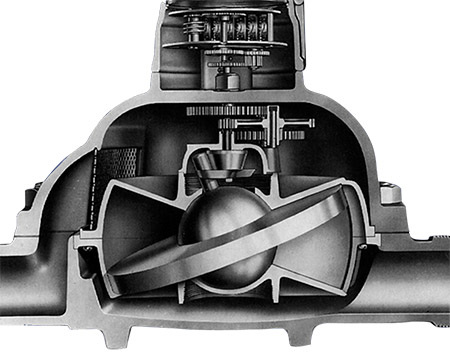

NUTATING DISC

- Proven accurate and reliable for over a century

- Unaffected by the viscosity of flow profile disturbances

- Tolerant of suspended solids that can stall other meter types

- Withstands pressure up to 150 psi and temperature to 250 F

- Works with mechanical or electronic register

OSCILLATING PISTON

- 2 moving parts

- Positive displacement meter

- Hydraulically floating piston does not contact the chamber surfaces during operation

- Easily serviceable because its simple construction requires no special knowledge or tools

- Tested under field conditions to optimize the design

- Dual case design

- The measuring element is replaceable and doesn’t require the meter to be removed from the line

- Components undergo strengthening treatment to increase durability

- Tolerant of low viscosity, abrasive, non-lubricating compressed gas

- Nituff coating reduces friction and protects from particulate damage

- Works with mechanical and electronic registers

CORIOLIS MASS FLOW

- Proven accurate and reliable for over a century

- Highly accurate flowmeter technology

- Direct mass measurement

- Increased efficiency

- All-electronic system

- Exceptional accuracy: 0.1 – 0.2%

- Wide flow range

- Eliminates errors due to temperature

- No wearing parts

- Maintenance-free

- Not affected by abrasives or contaminants

- Can measure density and purity

LIQUID FLOW MEASUREMENT

There are multiple methods used to measure the flow of a liquid.

Positive Displacement

Positive displacement (PD) flow meters measure the volumetric flow rate of a moving fluid by dividing the media into fixed, metered volumes (finite increments or volumes of the fluid). These devices consist of a chamber(s) that obstructs the media flow and a rotating or reciprocating mechanism that allows the passage of fixed-volume amounts. The number of parcels that pass through the chamber determines the media volume. The rate of revolution or reciprocation determines the flow rate.

Nutating Disc

Liquid enters a precision-machined measuring chamber containing a disc which nutates (wobbles). The measuring chamber contains an exact known quantity of fluid. Fluid pressure causes the disc to nutate and the control roller causes the nutating disc to make a complete cycle. The measuring chamber is filled and emptied each cycle. The nutations of the disc are transmitted by a gear train to a totalizer or pulse transmitter.

WHY CHOOSE US AS YOUR SUPPLIER

Extensive Stock & Quick Delivery

We maintain a comprehensive inventory of Red Seal products, ensuring prompt delivery to minimize your operational downtime.

Expert After-Sales Support

Our commitment includes installation assistance and ongoing maintenance, ensuring your Red Seal products perform optimally.

Trusted Partnership with Red Seal

As a recognized supplier, we provide access to the latest innovations backed by Red Seal’s industry expertise.

Commitment to Quality and Sustainability

We align with Red Seal’s focus on sustainability, offering high-quality products that support environmentally responsible practices.

Contact a Dedicated Liquid Handling Equipment Representative

Liquid Handling Equipment offers an extensive range of products through

partnerships with industry-leading manufacturers. Depend on us to deliver

solutions that enhance your facility’s operations and efficiency.