ROTAN

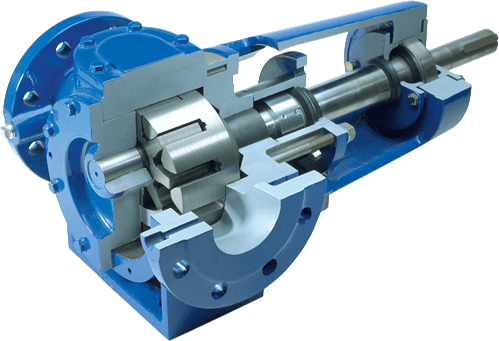

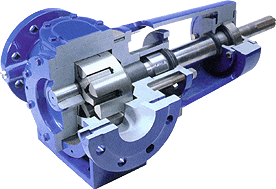

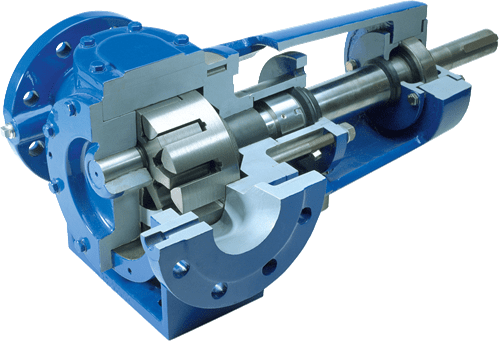

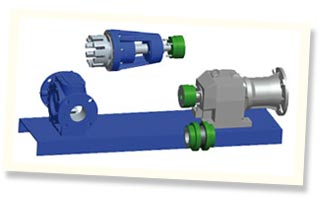

True back-pull-out feature allow inspection/repair of the rotating cartridge without disturbing the piping or coupling alignment

ROTAN® Benefits:

- Reduced downtime costs

- Reduced labor costs

- Spares optimization

ROTAN - CD

Internal gear pump designed to handle corrosive liquids.

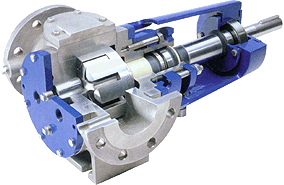

ROTAN CD – Chemical Duty. Internal gear pumps in stainless steel, designed to handle corrosive liquids.

CD pumps are designed for handling corrosive liquids, primarily found in the chemical processing, food, and pharmaceutical industries.

Available with 90° angular configuration.

ROTAN - ED

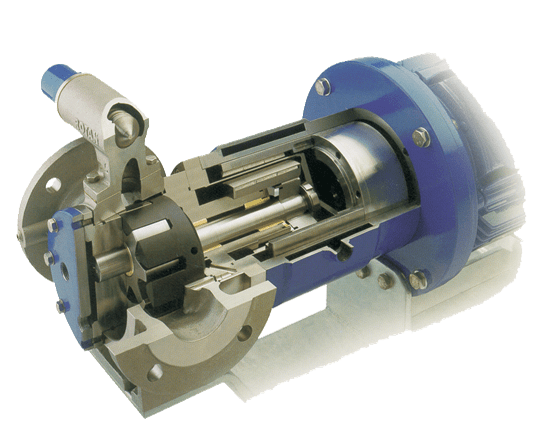

Magnetic Drive pumps are environmentally friendly pumps used for ultimate protection against leakage.

ED pumps are designed to pump flammable, toxic or groundwater polluting liquids, where no leakages can be risked.

ED pumps are typically used for pumping isocyanates, solvents as phenol and xylene, herbicides, pesticides, fungicides, benzene and other hazardous organic liquids including mildly abrasive paints and sweeteners.

Their use is extended to applications where leakage would be costly, e.g. highly refined chemicals, or where long overhaul intervals are required, reducing maintenance labor costs and loss of process time.

ROTAN - GP

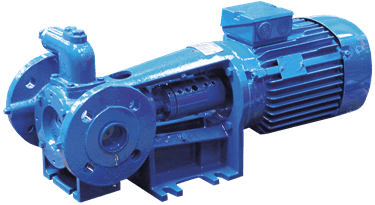

Internal gear pumps in cast iron, for clean, non-abrasive liquids.

The simple and compact construction makes it a low-cost pump, often used in modified versions by OEM customers.

GP pumps are designed for use with IEC or NEMA flange motors.

ROTAN - HD

Heavy duty pumps in cast iron, for a wide range of viscous, non-corrosive liquids. HD pumps are specifically designed for difficult applications and those involving high viscosity liquids.

Typical applications include pumping oils, asphalts (Asphalt pumps), chocolates(CHD pumps), paints, lacquers, molasses, soaps, and other industrial viscous process fluids.

HD pumps are known by their sturdy and simple construction.

ROTAN - PD

For refinery and petrochemical applications.

Petrochemical Duty PD are internal gear pumps designed for refinery and petrochemical applications, all pressure-containing components are carbon steel. Design pressure according to ANSI 300 Lbs or Pn40.

PD pumps are available to meet API 676 standards with exceptions.

Available with 90° angular configuration.

PUMPS FOR ANY APPLICATION:

SERVICE ON PUMPS WITHOUT BRAKING ANY PIPE CONNECTIONS

Operations like oil blending, additive mixing and filling of the finish lube oils are fully automatic batching processes, performed within parallel lines, each consisting of one blender and one weigh hopper. The process requires quality pumps – and around the world DESMI has been a reliable partner for many years as our ROTAN® GP and HD series are designed for giving an accurate and constant flow to support this process.

Pumps for any application

The key factors in all areas of the process industry are production reliability, productivity and performance.

These are precisely the areas addressed by our range of products, systems and services. Value-added liquid transport solutions for local and global companies are our scope of supply.

WHY CHOOSE US AS YOUR SUPPLIER

Extensive Stock & Quick Delivery

We maintain a comprehensive inventory of Rotan products, ensuring prompt delivery to minimize your operational downtime.

Expert After-Sales Support

Our commitment includes installation assistance and ongoing maintenance, ensuring your Rotan products perform optimally.

Trusted Partnership with Ebara

As a recognized supplier, we provide access to the latest innovations backed by Rotan’s industry expertise.

Commitment to Quality and Sustainability

We align with Rotan’s focus on sustainability, offering high-quality products that support environmentally responsible practices.

Contact a Dedicated Liquid Handling Equipment Representative

Liquid Handling Equipment offers an extensive range of products through

partnerships with industry-leading manufacturers. Depend on us to deliver

solutions that enhance your facility’s operations and efficiency.